Disc Centrifugal Slurry Pumps

Advanced Control with Apex Filter Press Pumps and VFD Technology

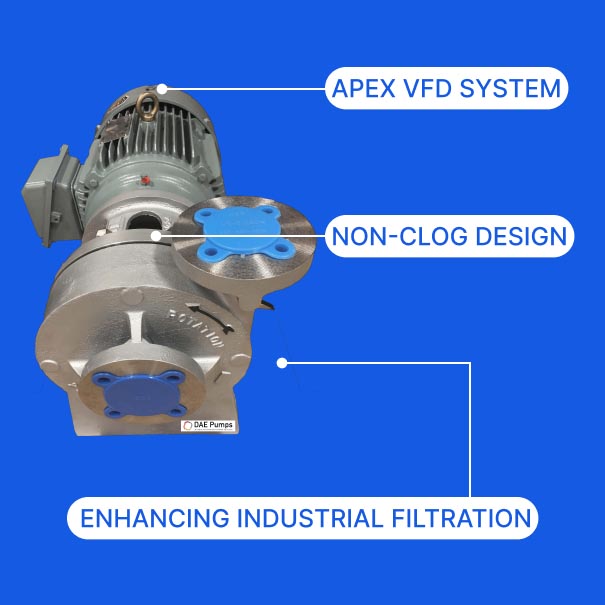

The Apex Filter Press Pumps are engineered to fit a wide range of filter press sizes and feature advanced Variable Frequency Drive (VFD) technology. This allows for variable speed operation, starting with high flow and low pressure, to gently form the filter cake, thereby preventing premature clogging of the filter cloth by avoiding the early buildup of a dense solids layer.

During the filter press cycle, the VFD controller gradually increases the feed pressure in sync with the pump. This controlled pressure ramp, which can be adjusted based on slurry type and solids concentration, optimizes filtration efficiency.

Typically, the process begins at approximately 25 PSI and gradually increases to a shut-off pressure of around 100 PSI, depending on the specific needs of the filter press. When the set pressure is reached, the pump automatically shuts off, ensuring accurate and efficient operation.

This automatic pressure management improves filtration performance and prolongs filter cloth life by reducing clogging and maintaining consistent filtration quality. The Apex VFD system is easily integrated with both existing and new filter presses, offering a flexible and effective solution for enhancing industrial filtration.

Low NPSH Design for Reliable Pumping

In challenging conditions such as those found in Saudi Arabia, uneven pressure caused by moving vanes can lead to cavitation at low-pressure points. Our Industrial Disc Centrifugal Pumps Saudi Arabia feature disc impellers with inherently low Net Positive Suction Head Required (NPSHR). Additionally, the Apex design includes an integral axial flow inducer that enhances low NPSH capabilities, delivering robust performance for demanding slurry applications.

The Apex disc impeller creates a uniform tangential pressure field throughout the pump, ensuring only positive pressure gradients are present. This stable pressure distribution is critical for maintaining efficiency and durability in tough operational environments.

Optimized Performance with High-Viscosity Fluids

Traditional vane impellers struggle with viscous liquids, resulting in lower efficiency and increased NPSH demands, especially with fluids having a specific gravity of around 500 SSU. The Disc Impeller Slurry Pumps from Saudi Dredge in Saudi Arabia overcome these limits. Designed with precise disk spacing, these pumps handle viscosities ranging from those of water-like fluids to 400,000 SSU with ease.

Flow dynamics adapt to fluid thickness, remaining slightly turbulent with thin liquids and shifting to laminar flow with heavier fluids, ensuring steady efficiency and consistent operation across various fluid types. This adaptability makes our Apex disc pumps ideal for a wide range of industrial slurry and viscous liquid applications.

Exceptional Durability in Abrasive Conditions

Abrasive slurries damage pump surfaces quickly, but the Apex rotating disc pump’s design mitigates wear by creating a boundary layer—a stable, calm fluid layer along the disc walls. This design reduces sudden flow changes and accelerations, preserving the boundary layer’s protective effect and enhancing resistance to abrasion.

This results in outstanding durability and reliability for Disc Centrifugal Slurry Pumps Saudi Arabia, making them perfect for harsh environments with abrasive liquids and ensuring long-term operational stability.

Related Equipment

Dewatering Pumps

Explore Saudi Dredge’s comprehensive range of dewatering pumps, designed for irrigation, fountains, and liquid transfer applications throughout Saudi Arabia. Known for their reliability and cost efficiency, our pumps guarantee smooth and effective performance in any setting.